| Since 1993 Company LEG ltd. has been manufacturing different models of trolleybus inserts and offers a range able to provide not only all Ukrainian city electric transport enterprises, but allowing as well to export up to 100 000 items of inserts monthly. |

| Due to carbon self-lubricating properties the contact inserts provide current transmission from overhead wiring to feeding cable of current-collector head to ensure the least wear of contact wiring.

Company LEG ltd. performs a permanent outgoing inspection of inserts, as well an additional processing, to achieve the supreme strength capacities. The key indicator of performance is distance, which can be covered by a current-collector insert.

Its operational performance is influenced by a combination of factors such as: insert material (all-season, summer, winter), speed rate of special parts, condition of overhead wiring, etc. |

| Company LEG ltd. manufactures inserts of various constructive models according to technical conditions ТУ У 27.9-14111810-008:2020. |

|

|

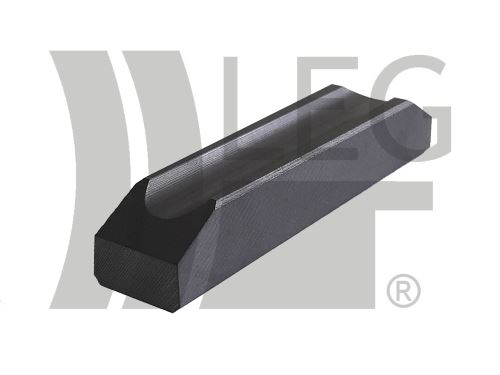

| VKT-1 trolleybus insert (standard model) |

|

Dimensions: width - 28 mm, length - 87 mm, shoulder height - 14 mm.

VKT-1 and VKT-2 inserts differ in cross-sectional shape.

The advantages of a standard insert model: low cost.

The disadvantages of a standard insert model: probability of fracture when passing through the special parts of overhead wiring;

above-the-normal side wear of sidepieces when the insert walls destroy;

short service life of the insert.

|

| VKT-2 trolleybus insert |

| Dimensions:

width - 28 mm, length - 87 mm, shoulder height - 14 mm.VKT-2 inserts differ in cross-sectional shape from VKT-1. |

| VKT-3 trolleybus insert |

| Dimensions:

width - 28 mm, length - 87 mm, shoulder height - 14 mm.

The VKT-3 insert differs from VKT-1 and VKT-2 inserts in longer service life. Ukrainian city electric transport enterprises gave positive reviews about its exploitation. |

| VKT-4 trolleybus insert |

| Dimensions:

width - 26 mm, length - 87 mm, shoulder height - 18 mm.The VKT-4 insert differs from VKT-1, VKT-2, VKT-3 inserts in physical dimensions.

Manufactured specially for ME Kievpasstrans. |

| VKT-5 insert (improved model) |

| Dimensions:

width - 28 mm, length - 87 mm, shoulder height - 20 mm.

Advantages:

- enhanced thickness of walls in the upper part;

- the insert shape allows smooth entrance and passage of special parts in the overhead wiring;

- reduces probability of wire sidewise friction with sidepieces;

- extends the service life of all current-collector parts via reduction of sparkling, caused by contact loss;

- extended life service of the insert.

|

| V-shaped insert (euro) |

| Dimensions:*

width - 20,3-25,7; length - 102 mm, shoulder height - 17,5 mm.

(* The dimensions of V-shaped insert (euro) are customer-specific and can be manufactured at the request of the Customer).Advantages:

- easy and quick replacement of the insert;

- reduces possibility of sidewise friction with sidepieces;

- extends the life service of all current-collector parts via reduction of sparkling, caused by a contact loss;

- extended life service of the insert.

|

|

For current collection from contact wire the VKT inserts are fixed in the current-collector heads.

Company LEG ltd. recommends to use the VKT-5 trolleybus contact insert (the improved model) paired with current-collector head, kitted up with a shunt. |

|

|

| Current-collector head with a shunt |

| Application of current-collector head with a shunt provides:

- decrease in losses of electric current when transmitted from overhead wiring to current collector;

- reduction of overheating the contact parts of the insert;

- wear reduction of the insert;

- life service extension of the current-collector head.

|

Alongside with promotion of a new (improved) model of insert VKT-5, Company LEG ltd. has been developed a new (all-season) material, which technical features are not affected by weather conditions (precipitations). The trolleybus inserts made of new material under normal conditions of use don't run out of its potential operational resource and are the best solution for exploitation in adverse climate conditions.

The life service of inserts is expected to provide the trolleybus mileage of not less than 300 km in dry weather in the absence of eccentric displacement at wire intersections. The warranty life of metal graphite (winter) inserts under the same conditions is to provide the trolleybus mileage of not less than 800 km. |