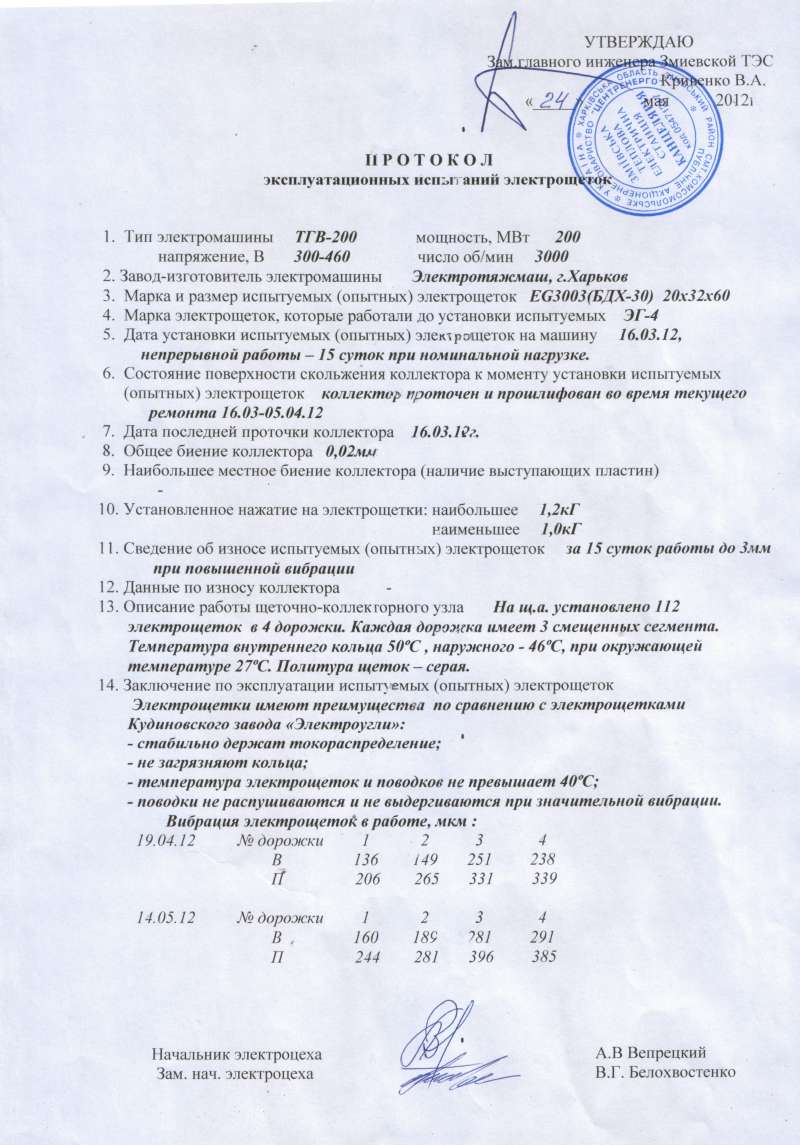

Zmievskaya TP. May 2012.

A report of exploitation tests of brushes EG3003.

Brushes EG3003 of "LEG" Ltd. company production have advantages in comparison with brushes EG-4 of Kudinovskiy plant "Electrougli". After 15 days of operation tear and wear of brushes EG3003 is less than 3mm during extensive vibration. |

|

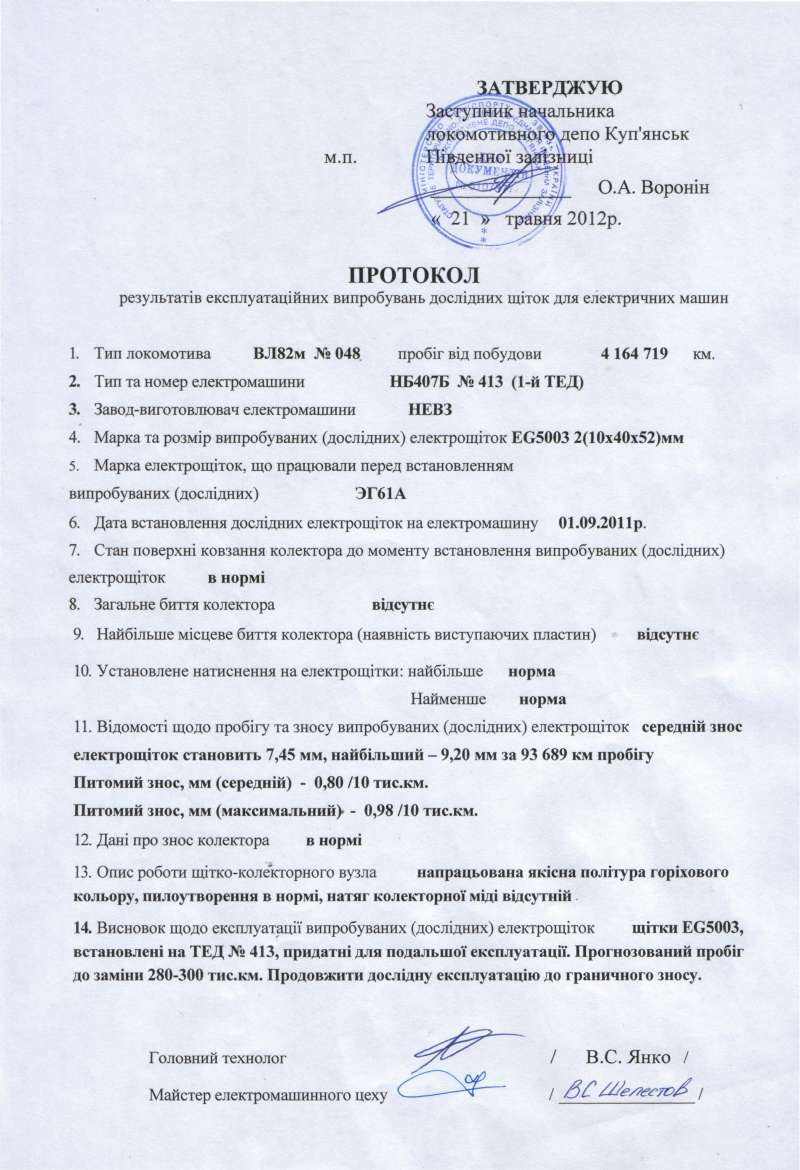

Locomotive barn of Kupyansk south railway. May 2012.

A report of exploitation test results of experimental brushes EG5003.

The maximum tear and wear of brushes EG5003 of "LEG" Ltd. company production is 0,98mm for 10000km. Brushes EG5003 are suitable for future exploitation. Projected pass before a substitution is 280-300 thousand km. |

|

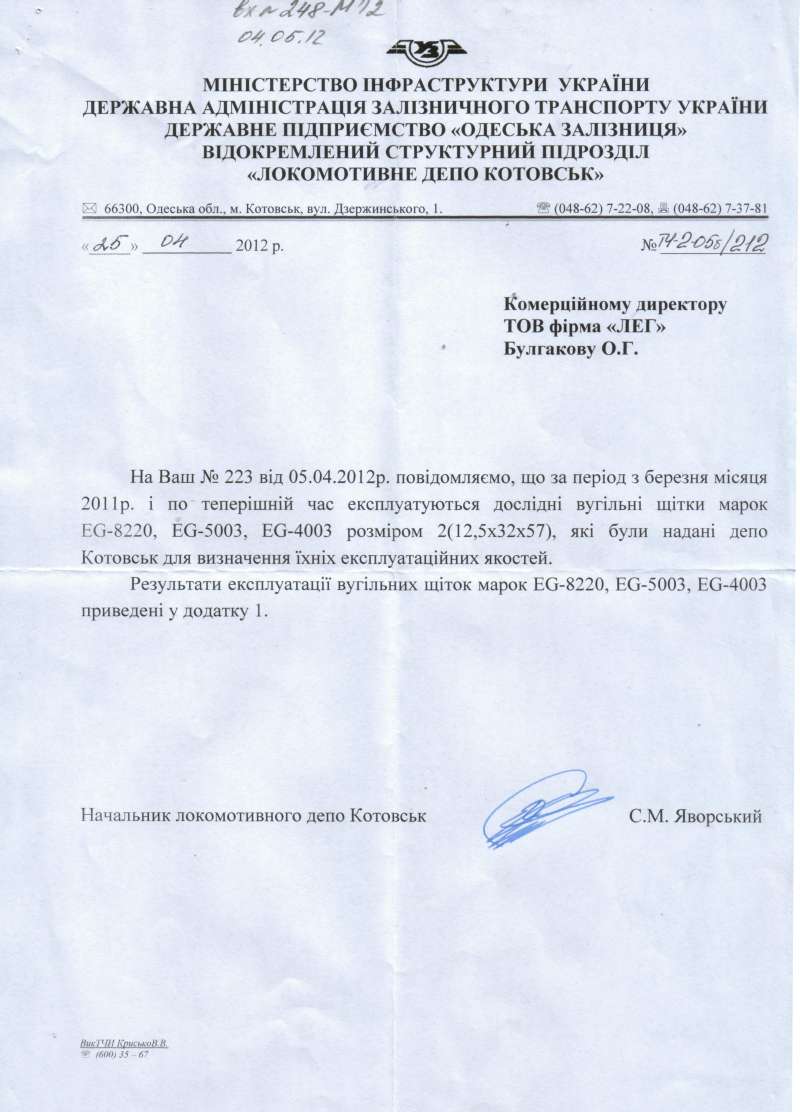

Locomotive barn «Kotovsk» OR. April 2012 г.

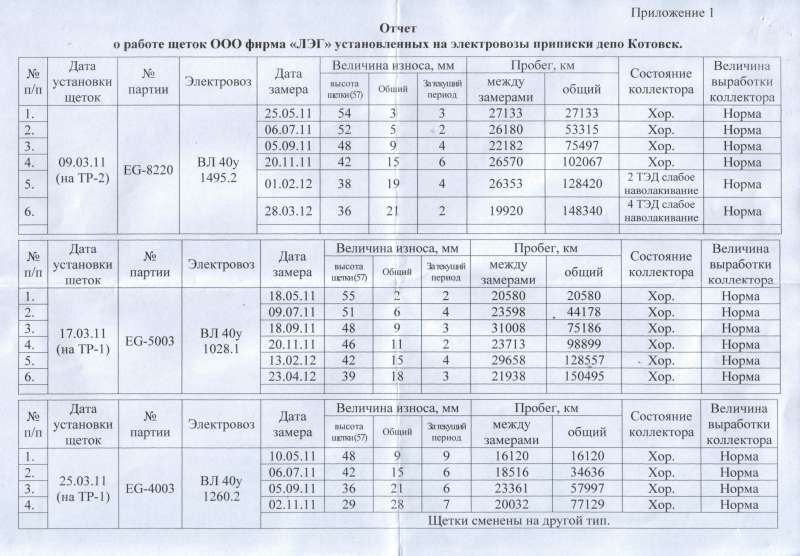

Report about brushes operation of "LEG" Ltd. company, installed at locomotives in a barn "Kotovsk".

From March 2011 till April 2012 exploitation tests of EG8220, EG5003 and EG4003 brushes of "LEG" Ltd. company production were conducted at locomotives of a barn "Kotovsk".

Tests showed that brushes EG5003, with o total pass of 150495km, have the minimum tear and wear of 18mm, with a brush height of 57mm. |

|

|

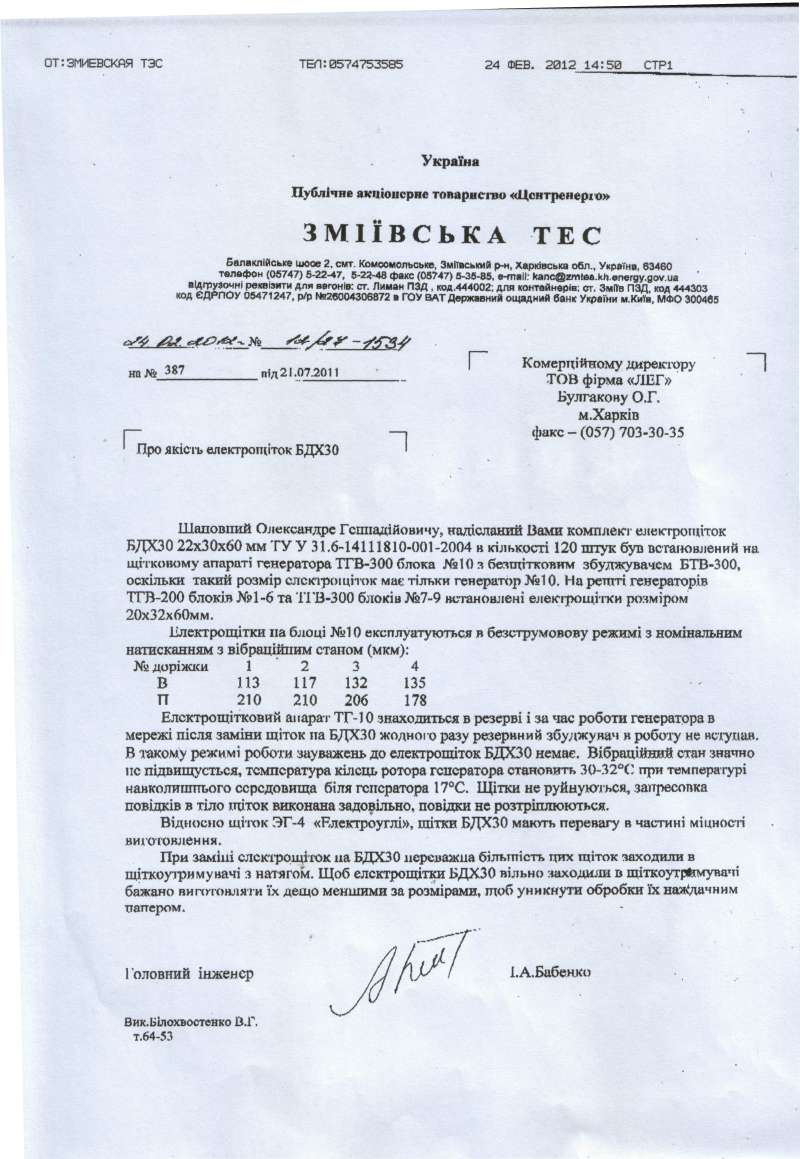

Zmeevskaya TP. February 2012.

About quality of brushes BDKh 30.

As for brushes EG-4 «Electrougli», brushes BDKh 30 of "LEG" Ltd. company production have advantages in solidity of manufacturing. Vibration state of generator at which brushes were installed doesn't go up and brushes are not destroyed. |

|

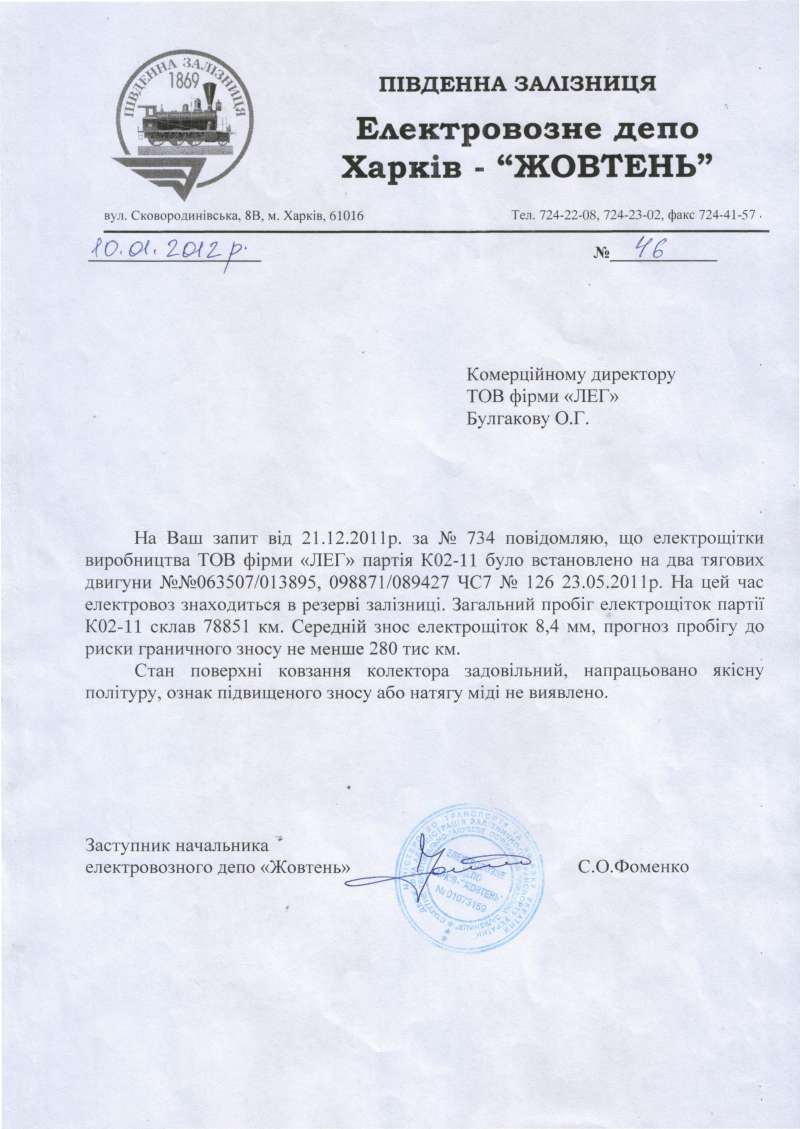

Locomotive barn "Oktyabr', January 2012.

Brushes production "LEG" company Ltd. installed on electric traction engines.

The total mileage brushes batch was 78851 km. Average wear brushes is - 8.4 mm. The forecast of stable work is about 280 000 km. |

|

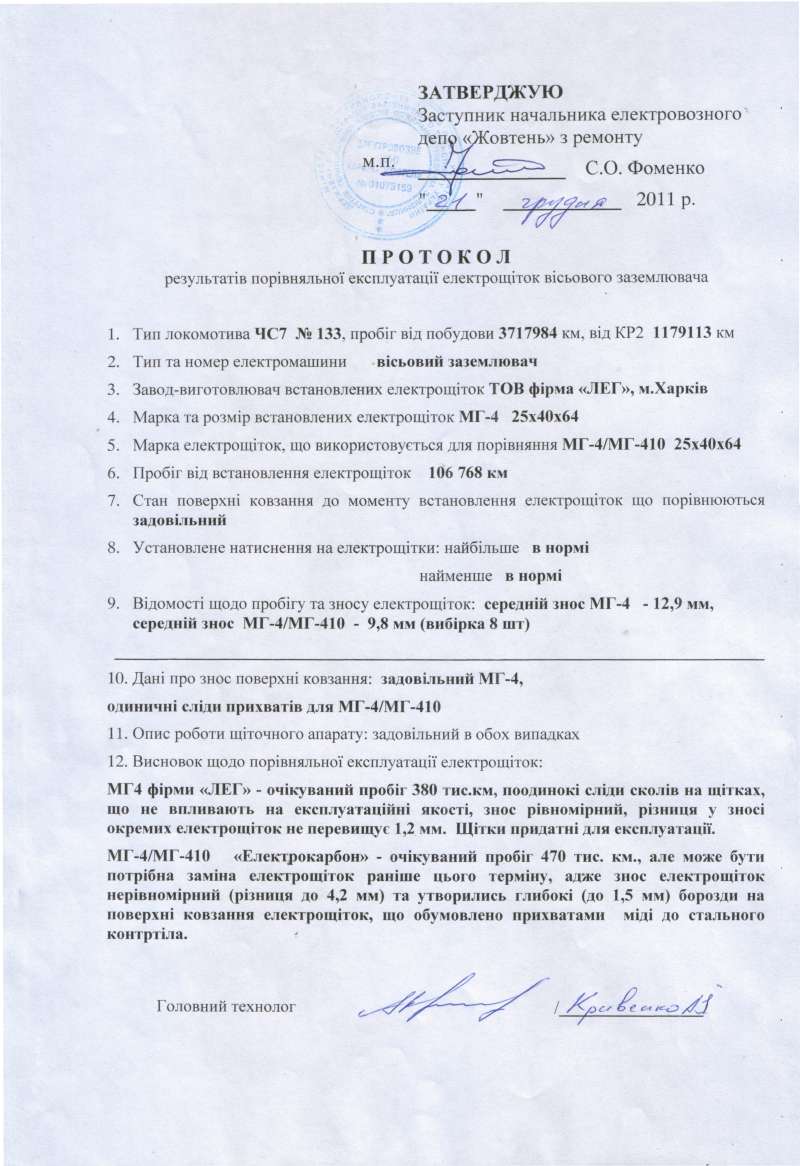

Locomotive barn "Oktyabr'". December 2011.

A report of results of a comparative exploitation of axial grounding brushes MG4.

After comparative tests of MG4 brushes of "LEG" Ltd. company production there is a conclusion that they are exploitable. Expected pass of brushes is 380 000km. Expected pass of brushes MG-4/MG-410 of "Electrocarbon" production is 470km. According to test results it became clear that replacement of brushes can be necessary before this term, because tear and wear of brushes is uneven (difference is to 4,2mm). |

|

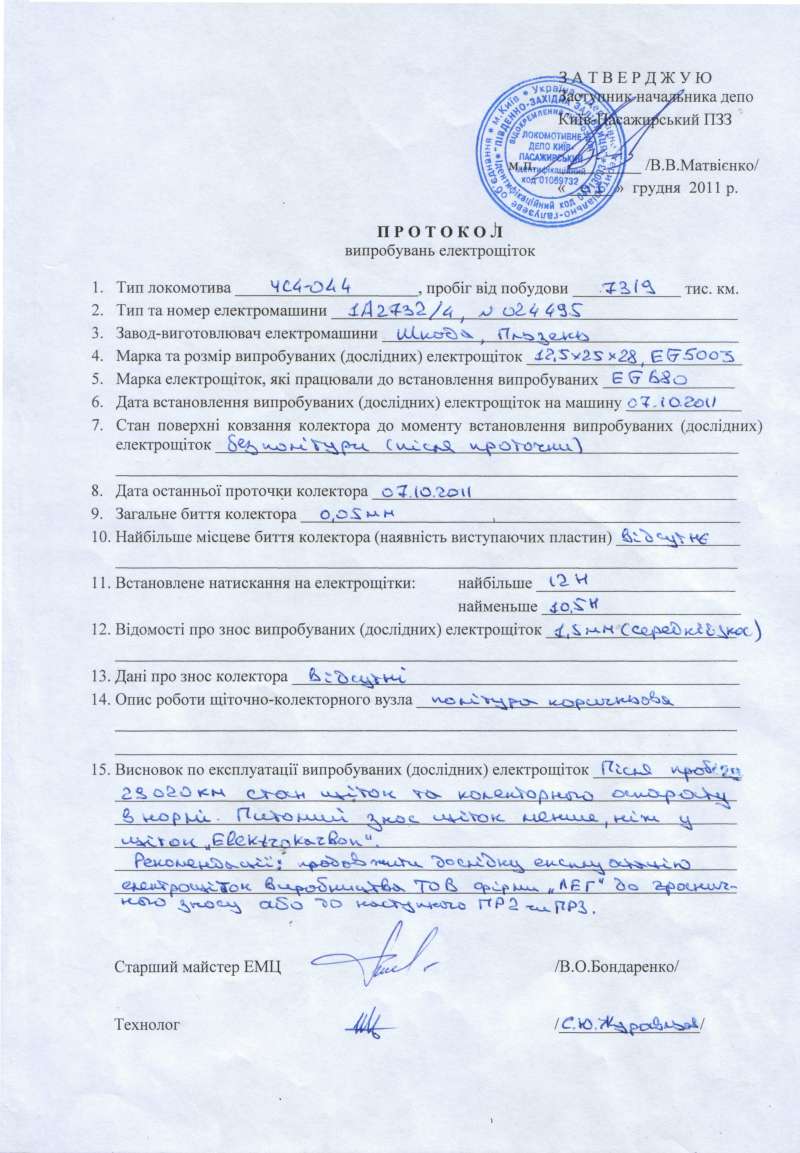

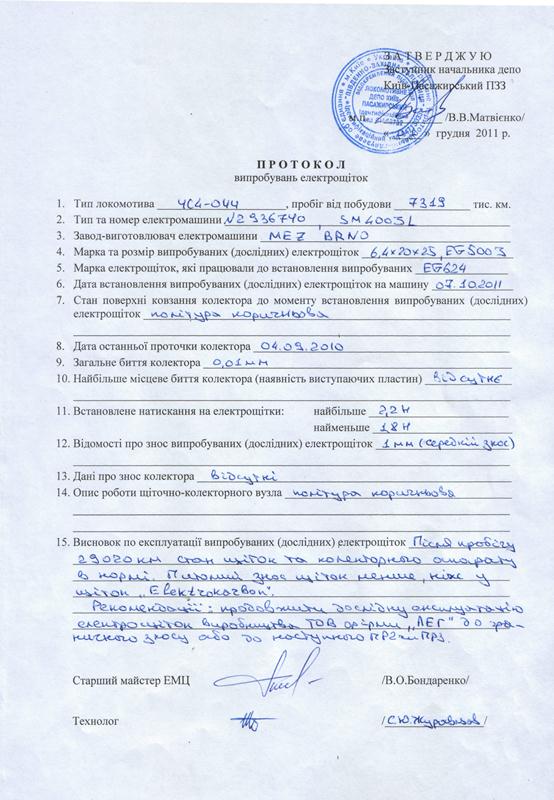

Locomotive shed Kiev-Passazhurskiy SWК. December 2011.

Reports of EG5003 brushes tests.

Tear and wear of EG5003 brushes of "LEG" Ltd. company is less in comparison with brushes of "Electrocarbon" production. After a pass of 29020km the state of brushes and the collector is in respect to the norm. |

|  |

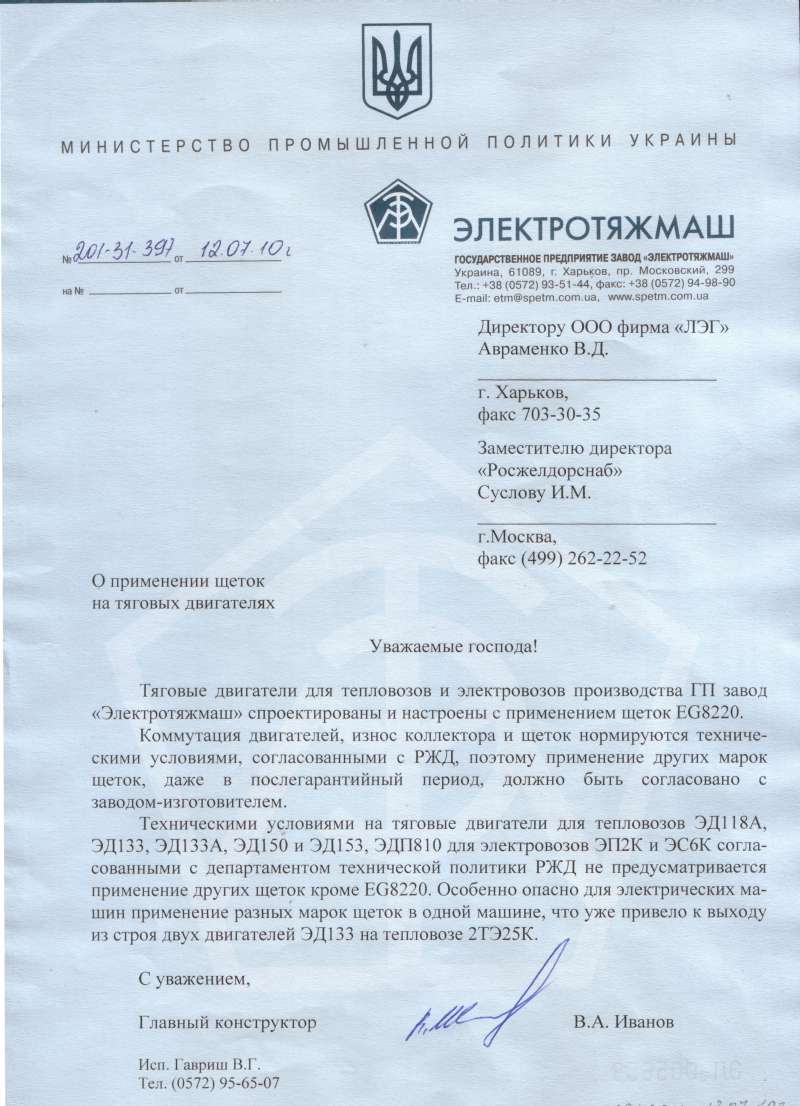

State enterprise plant «Electrotyazhmash». July 2010.

About application of EG8220 brushes at traction engines.

Only EG8220 brushes are supposed to be used at traction engines of diesel locomotives and electric locomotives by State enterprise plant «Electrotyazhmash». |

|

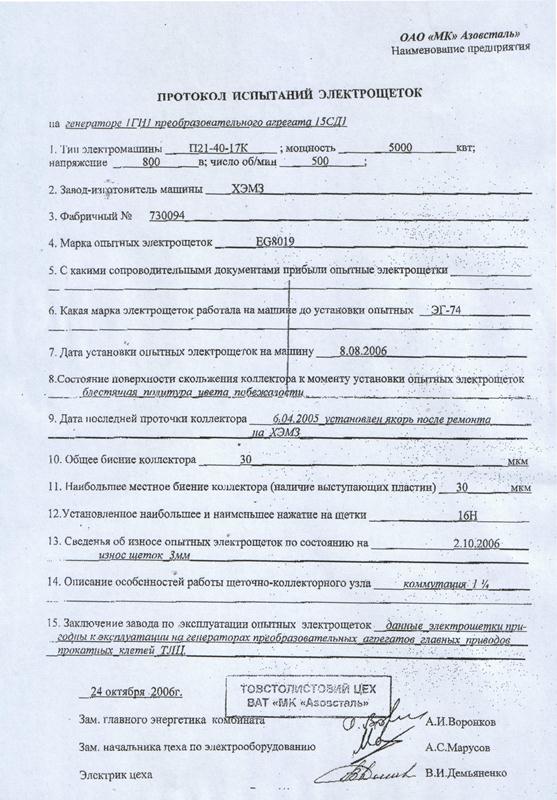

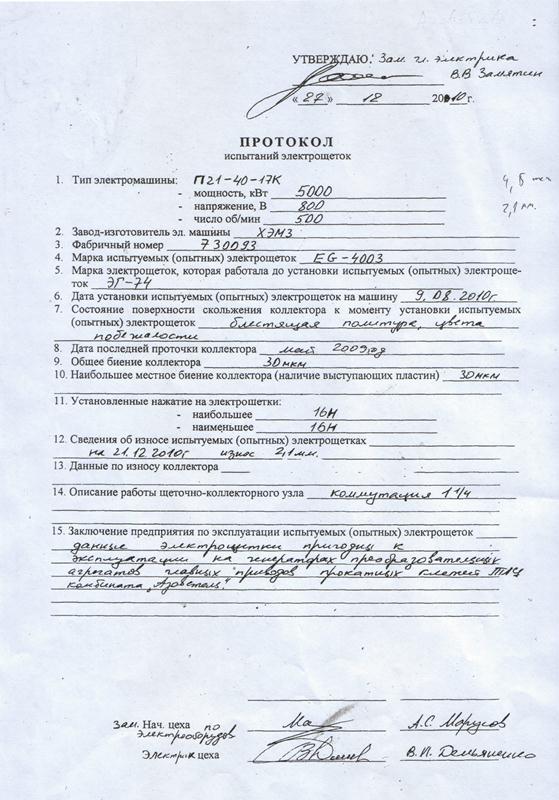

JSC "MC "Azovstal'".

Comparative tests of brushes EG4003 of Company "LEG" Ltd. production and brushes EG8019 of French corporation MERSEN production.

Comparative tests of brushes EG4003 of Company "LEG" Ltd. production and brushes EG8019 of French corporation Carbone Lorraine (MERSEN today) production, conducted at JSC "MC "Azovstal'" at generators of conversion units showed that with a uniform tear and wear of a brush EG4003 brushes EG8019 tearing is 3 times less and EG 74 brushes tearing is 20 times less which were installed at these generators before. |

|  |

|

|