Furnaces and carbon mountings

Furnaces and carbon accessories are used in vacuum or inert environment at a temperature of not more than 2000 ° CMain applications:

• Thermal vacuum processing and heat hardening of gas-turbine blades, gas-turbine airplane and gas-compressor drives;

• Obtaining heat-resistant alloys and parts by crystallization direction;

• Obtaining cemented-carbide tools.

| Graphite heaters are used instead of tungsten and molybdenic ones for fuse of rare metals and solid state metals in vacuum and other closed electric furnaces. They can operate under temperature not higher than 2000-2200°С. Graphite heaters stably work in vacuum to 1х10-2mm of mercury, under temperatures to 2000°С, rate of flow of 1500-2000А, under voltage of 12-24V. There are three main types of produced graphite heaters: cylindrical, slotted and spiraling.. Main dimensions of heaters are limited with maximum dimensions of subproducts. | |

| Graphite and carbon (UUKM) facilities (screens, firepots, etc) – are made for graphite firepots, charging boxes and tables, bearings, blades, graphite plugs, jackets and other fabricated shapes. | |

| Heat-insulting materials | |

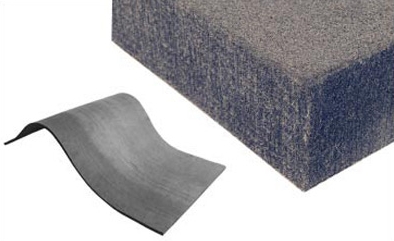

| Carbon fibrous foiled heat insulting (UFTT) – light heat-insulting material is constructive thermally insulting element, which is produced in sheets of different thickness and in cylindrical form. Covering face from operator side and also inner layers of graphite foils increase resistance to influence of fusions and penetration of steam which destroy heat insulting. | |

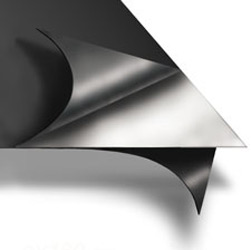

| Graphite foil (GF) – is a flexible material that is produced in sheets of different thickness. It is used for manufacturing of heat screens, covering materials for UFTT, spacer material between graphite heating elements and current leads for decrease of contact resistance at the place of parts connection. | |

| Protecting coating solution UFTT – suspension of graphite of fine fraction in organic solution. It is used for butts UFTT applying on a surface. After drying it creates gas proof layer, which resists penetration of steams in recesses of heat proof. It is also used for improvement of contract strength between graphite heating elements. | |

| High-temperature ceramic (HTK) – constructional dielectric material on the basis of aluminic oxide. Products made of high-temperature ceramic are used as electrically insulting elements in heat-treatment installations. | |