Carbon brushes for electrical machines

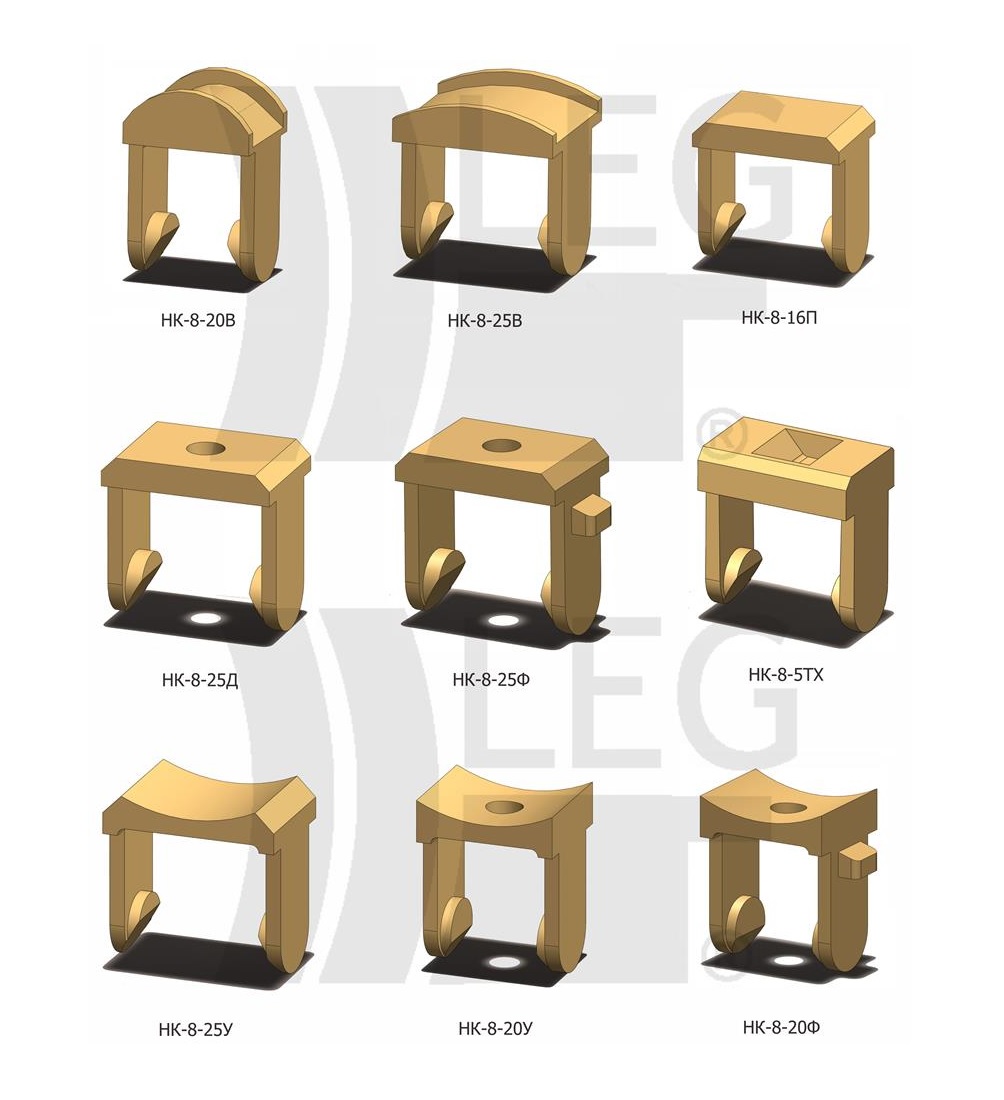

Company LEG ltd. manufactures brushes of any size, production by Client’s individual order is also possible.

During existence of LEG Ltd. company has created carbon brush materials for all modern areas of application. We think that our offered solutions are the most efficient in the majority of application areas in the world for today.

For convenience of consumers we offer the classification of carbon brushes materials according to basic conditions of brush movement but not according to the technology of production.Within scopes of the class carbon brushes differ in price and quality characteristics. That’s why every client of ours will be able to find the qualitative production for reasonable prices for any area of application.

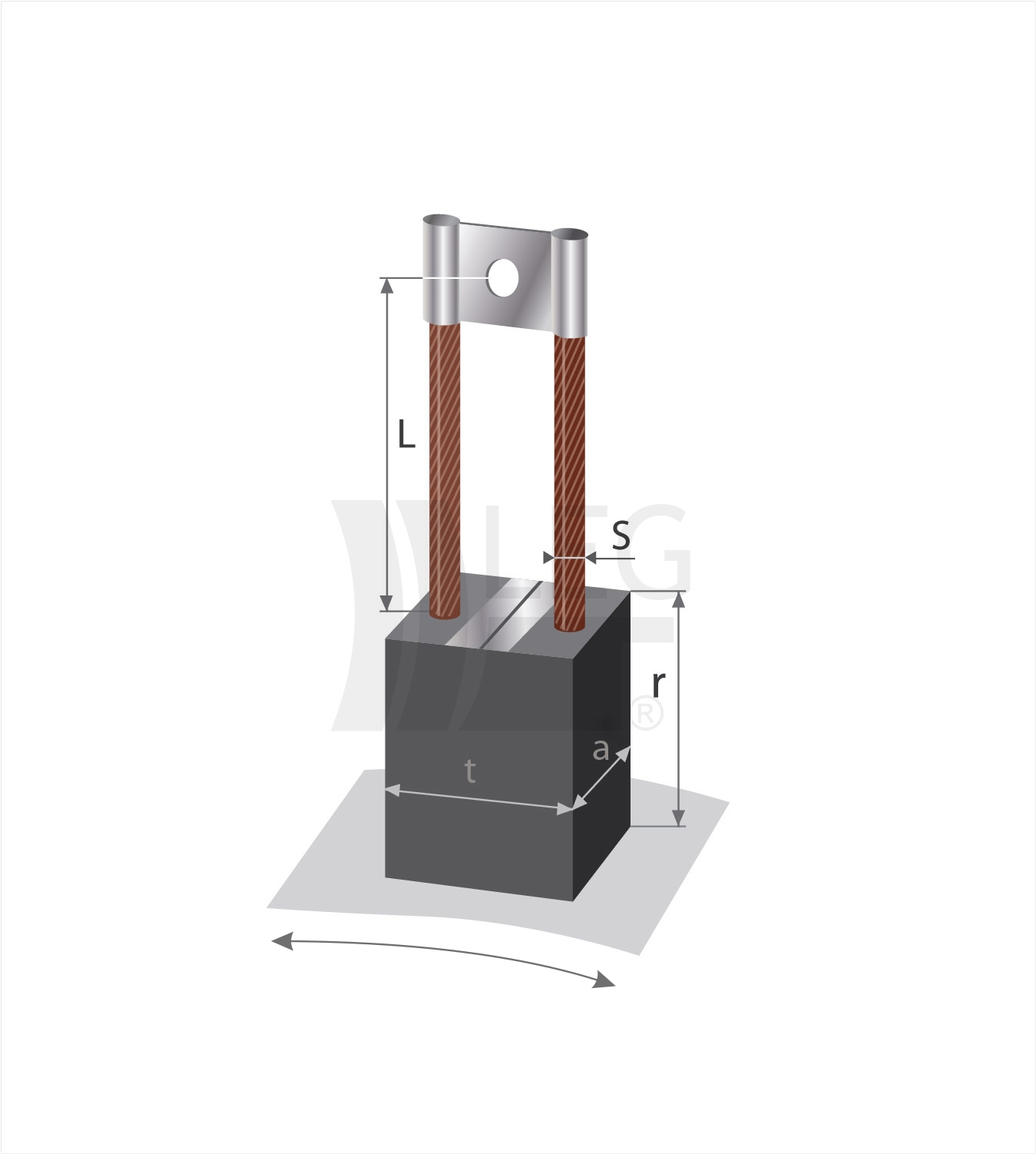

Graphite and copper graphite brushes for electric motors: selection and technical characteristics

Brushes for electric motors are important components that provide reliable contact and transmission of electric current from the power source to the motor winding. They are used in various industrial sectors, including manufacturing, transportation, and energy.

Graphite brushes are known for their high resistance to friction and heat, making them ideal for use. They have excellent conductivity and durability, allowing them to work in various operating conditions.

Copper-graphite brushes combine the high conductivity of copper with the properties of graphite. This allows them to provide stable operation of the electric motor under high loads and temperatures.

When choosing brushes it is important to consider a number of factors, including the power of the electric motor, operating conditions, and reliability requirements. The availability of different types such as graphite, copper-graphite, and carbon-graphite, allows you to select the optimal option for a specific application.

Stamps and technical properties of electric brushes produced by Company LEG Ltd.

| Stamps of brush | Specific electrical resistance, mkOm*m | Voltage drop on a pair of brushes, W | Friction factor, not more | Wear on the SCC installation, mm, not more | Line speed, m/sec, not more | Current density, A/cm2, not more | Recommended specific pressure upon brush, kPa |

| БДХ 30 (BDH 30) | from 5 to 20 | from 0,9 to 2,3 | 0,20 | 0,30 | 80 | 12 | from 15 to 25 |

| БДХ 40 (BDH 40) | from 25 to 45 | from 0,8 to 3,0 | 0,20 | 0,30 | 40 | 12 | from 15 to 40 |

| БДХ 50 (BDH 50) БДХ 50Ф (BDH 50F) | from 40 to 85 | from 1,0 to 3,3 | 0,20 | 0,30 | 50 | 15 | from 35 to 45 |

| МГ (MG) | from 0,03 to 0,12 | not more 0,3 | 0,20 | 0,80 | 50 | 50 | from 15 to 25 |

| МГ-4 (MG-4) | from 0,3 to 1,3 | not more 1,6 | 0,20 | 0,30 | 50 | 40 | from 20 to 40 |

| МГСО (MGSO) | from 0,1 to 0,3 | not more 0,35 | 0,24 | 0,60 | 50 | 45 | from 15 to 40 |

| М1 | from 3 to 13 | from 1,0 to 1,8 | 0,25 | 0,18 | 50 | 30 | from 15 to 50 |

| М1А | from 1,5 to 8 | from 0,8 to 1,8 | 0,22 | 0,18 | 50 | 30 | from 25 to 70 |

| EG 8220 | from 42 to 72 | from 2,3 to 3,6 | 0,15 | 0,30 | 60 | 20 | from 20 to 60 |

| EG 3003 | from 10 to 20 | from 1,1 to 2,3 | 0,15 | 0,30 | 90 | 15 | from 11 to 25 |

| EG 4003 | from 30 to 50 | from 0,7 to 2,3 | 0,15 | 0,30 | 40 | 12 | from 26 to 40 |

| EG 5003 | from 42 to 85 | from 2,0 to 3,3 | 0,20 | 0,30 | 50 | 14 | from 18 to 60 |

| EG 5010 | from 30 to 65 | from 1,0 to 2,6 | 0,15 | 0,30 | 50 | 15 | from 25 to 50 |

| EG 5020 | from 45 to 70 | from 1,8 to 3,0 | 0,15 | 0,30 | 60 | 20 | from 34 to 49 |

| EG 313 | from 42 to 52 | from 2,3 to 3,0 | 0,12 | 0,30 | 50 | 12 | from 17 to 30 |

| LFC 554 | from 17 to 23 | from 2,3 to 3,0 | 0,20 | 0,30 | 90 | 13 | from 9 to 20 |

| F2003 | from 5 to 16 | from 1,2 to 2,5 | 0,20 | 0,30 | 80 | 17 | from 10 to 25 |

| FE6X | from 55 to 100 | from 1,6 to 3,6 | 0,22 | 0,25 | 55 | 30 | from 25 to 60 |

| EF54 | from 25 to 50 | from 1,2 to 2,6 | 0,2 | 0,30 | 60 | 15 | from 20 to 50 |

| EF-61 | from 50 to 100 | from 1,5 to 3,2 | 0,23 | 0,28 | 55 | 15 | from 20 to 50 |

| EF-68 | from 38 to 78 | from 1,6 to 3,8 | 0,23 | 0,25 | 20 | 30 | from 25 to 60 |

| 50 | 15 | ||||||

| EG 4010 | from 20 to 50 | from 0,8 to 2,4 | 0,16 | 0,30 | 40 | 14 | from 25 to 40 |

| EG 4012 | from 25 to 60 | from 1,0 to 3,3 | 0,17 | 0,30 | 40 | 12 | from 30 to 50 |

| EG 5012 | from 27 to 65 | from 1,1 to 3,6 | 0,16 | 0,30 | 55 | 12 | from 35 to 55 |

| EG 9040 | from 10 to 20 | from 1,0 to 2,2 | 0,15 | 0,30 | 40 | 15 | from 30 to 40 |

| ЭГ2А | from 12 to 26 | from 0,9 to 1,9 | 0,23 | 0,40 | 70 | 18 | from 20 to 50 |

| ЭГ2АФ | from 13 to 25 | from 1,1 to 2,1 | 0,23 | 0,40 | 90 | 18 | from 15 to 25 |

| ЭГ4 | from 6 to 16 | from 0,8 to 2,0 | 0,25 | 0,60 | 80 | 20 | from 15 to 25 |

| ЭГ8 | from 36 to 50 | from 1,0 to 1,8 | 0,25 | 0,40 | 70 | 15 | from 15 to 40 |

| ЭГ14 | from 20 to 38 | from 1,1 to 2,1 | 0,25 | 0,40 | 70 | 20 | from 20 to 50 |

| ЭГ61 | from 25 to 45 | from 1,3 to 3,1 | 0,17 | 0,40 | 70 | 21,5 | from 25 to 50 |

| ЭГ61А | from 36 to 60 | from 1,5 to 3,2 | 0,15 | 0,30 | 70 | 22 | from 20 to 50 |

| ЭГ64 | from 30 to 65 | from 1,0 to 2,6 | 0,15 | 0,30 | 70 | 20 | from 25 to 60 |

| ЭГ71 | from 20 to 35 | from 1,1 to 2,1 | 0,3 | 0,40 | 70 | 20 | from 20 to 30 |

| ЭГ74 | from 35 to 75 | from 1,2 to 2,4 | 0,22 | 0,40 | 70 | 22 | from 17,5 to 50 |

| ЭГ84 | from 30 to 70 | from 1,5 to 3,5 | 0,19 | 0,40 | 70 | 22 | from 20 to 60 |

| ЭГ841 | from 60 to 80 | from 1,7 to 3,7 | 0,17 | 0,35 | 70 | 22 | from 20 to 60 |

| ЭГ85 | from 35 to 75 | from 1,6 to 2,6 | 0,20 | 0,40 | 70 | 22 | from 17,5 to 50 |

| LE34 | from 6 to 16 | from 2,0 to 3,6 | 0,19 | 0,50 | 80 | 20 | from 15 to 25 |

| EH34 | from 8 to 18 | from 1,8 to 3,3 | 0,17 | 0,40 | 80 | 20 | from 15 to 35 |

| Г3 | from 8 to 20 | from 0,6 to 1,4 | 0,30 | 0,50 | 80 | 15 | from 15 to 25 |

| Г33 | not more 900 | from 3,0 to 6,0 | 0,25 | - | 60 | 10 | from 20 to 60 |

| МГС21Н (MGS21N) | not more 0,5 | not more 0,6 | - | - | 50 | 25 | from 15 to 40 |

| МГС5 (MGS5) | from 2 to15 | from 0,7 to 1,9 | 0,22 | 0,40 | 50 | 30 | from 20 to 50 |

| 611ОМ | from 8 to 28 | from 0,7 to 1,7 | 0,3 | 0,40 | 90 | 25 | from 12 to 25 |

| МГС22 | not more 5 | not more 1,5 | - | - | 50 | 25 | from 15 to 40 |

| ВТ5 | from 35 to 65 | from 1,2 to 2,8 | 0.25 | 0.4 | 50 | 30 | from 30 to 65 |

| Г27 | from 18 to 45 | from 1,4 to 3,4 | 0.22 | 0.3 | - | 30 | from 30 to 60 |

| Г21А | from 160 to 610 | from 2,5 to 5,5 | 0.25 | 0.45 | 6 | 5 | from 40 to 170 |

| МГС7 | from 1,5 to 20 | from 1,6 to 2,4 | 0.3 | 0.35 | 55 | 30 | from 20 to 60 |

| МГС8 | from 4 to 15 | from 1,8 to 2,8 | 0.2 | 0.5 | 55 | 28 | from 20 to 60 |